Technology is rapidly evolving; the way we learn and prepare for the workforce is changing at an unprecedented pace. Virtual Reality (VR), once the domain of gaming and entertainment, is now penetrating the job training scenario, particularly in skilled trades, becoming increasingly beneficial for jobs requiring extensive amount of hands-on-practice. VR is revolutionizing the certification process, and it could very well be the future of job training. Let us delve into the whys and hows of it.

The growing need for modern training solutions

The skilled trades sector faces unique challenges in training and certification. According to a recent report, candidate eager to take up skilled trade training “faced challenges accessing critical training with 52% of students reporting they were placed on a waitlist.” Industries like welding, electrical work, HVAC, and manufacturing often require hands-on experience in controlled environments. Traditional training methods, such as apprenticeships or classroom-based learning, can fall short in addressing these challenges due to:

– Limited Resources: Tools, materials, and workspace availability can hinder access to adequate practice.

– Safety Concerns: Novices learning complex machinery or hazardous tasks risk accidents, making real-world training costly and risky.

– High Costs: Consumables like metal, gas, or other materials for practice can strain training budgets.

What makes VR a game-changer for job training?

Virtual Reality is emerging as a powerful solution to address these challenges, providing immersive, cost-effective, and scalable training experiences.

Immersive and Realistic Training Environments: VR enables learners to practice in realistic, 3D environments that replicate actual job sites. For example, a trainee electrician can practice wiring circuits in a simulated construction site without any risk of electrocution. These lifelike scenarios foster deep learning, as they simulate the pressure, constraints, and unpredictability of real-world tasks.

Enhanced Safety Measures: Safety is paramount in the skilled trades, and VR offers a zero-risk environment. Trainees can make mistakes, test different approaches, and learn from their errors without putting themselves or others in harm’s way. This aspect is particularly crucial for hazardous jobs like welding, where mistakes can lead to severe injuries.

Cost-Effective Training: VR eliminates the need for physical materials and tools in the early stages of training. Instead of repeatedly using consumables, learners can practice virtually, reducing expenses significantly. Additionally, companies save on travel costs by training employees remotely using VR headsets.

Consistent Training Quality: Traditional training often depends on the expertise and teaching styles of individual instructors, leading to variability in learning outcomes. VR ensures consistency by providing standardized scenarios and instructions, guaranteeing all learners receive the same high-quality training.

Accelerated Learning Curves: Research shows that immersive VR training enhances knowledge retention. Learners absorb complex concepts faster and remember them longer when engaged in hands-on virtual tasks compared to passive learning methods like lectures or videos. This accelerated learning curve translates into quicker certification and a faster transition to the workforce.

How VR is transforming certification

Certification processes in skilled trades require demonstrating both theoretical knowledge and practical skills. VR is redefining how these requirements are met:

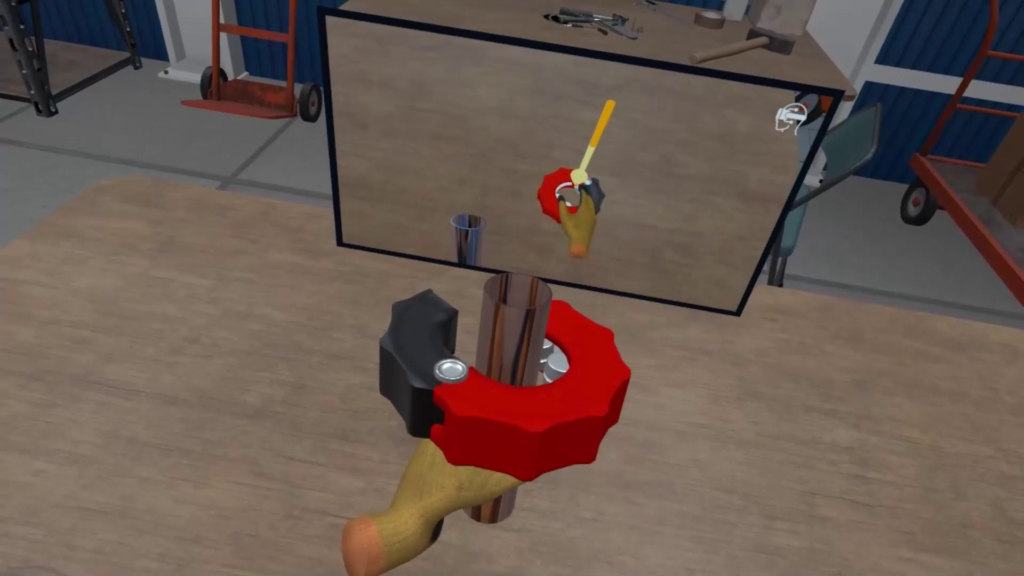

Simulated Assessments: VR allows trainees to complete practical tests in virtual environments that accurately reflect real-world conditions. For example, a plumber might be tasked with diagnosing and repairing a simulated pipe leak. These tests are monitored, recorded, and evaluated, offering objective assessments of the trainee’s performance.

Skill Tracking and Feedback: VR systems are equipped with analytics tools that track learner progress in real time. Metrics like accuracy, speed, and decision-making can be analyzed to identify strengths and areas for improvement. This detailed feedback helps learners refine their skills and prepare for certification exams with confidence.

Remote Proctoring and Accessibility: VR makes certification more accessible by enabling remote proctoring. Trainees can complete certification requirements from their homes or local training centers while being monitored virtually by assessors. This flexibility is a game-changer for individuals in rural areas or those with limited access to traditional training facilities.

Real-world applications of VR in skilled trades

Several industries are already leveraging VR for training and certification:

Plumbing: Plumbing training through VR enables trainees to practice diagnosing and repairing a wide range of issues, such as pipe leaks, clogged drains, and water heater malfunctions, in a risk-free virtual environment. Simulations can replicate complex systems with varying water pressure, material types, and environmental conditions, allowing trainees to build hands-on experience without wasting water or materials. Trainees can also learn proper safety protocols, such as handling pressurized systems or dealing with hazardous wastewater, ensuring they are job-ready before stepping onto a real site.

Electrical: In VR-based electrical training, learners can explore wiring, circuit assembly, and troubleshooting techniques in realistic environments, such as homes, factories, or construction sites. Simulations allow trainees to safely interact with high-voltage systems, identify faults, and understand load balancing without any risk of electrocution or fire hazards. They can also practice emergency protocols, like responding to electrical fires or short circuits, while receiving instant feedback on their techniques and decision-making, accelerating their path to professional certification.

Welding: VR-based welding training allows learners to master techniques like arc welding, TIG, and MIG in a safe and controlled environment. Trainees can practice welding various joints and materials under different conditions, such as overhead or vertical welding, without using consumables like metal or gas. Simulations provide real-time feedback on factors like precision, angle, and heat control, enabling learners to refine their skills and reduce waste. This immersive approach prepares trainees for real-world welding tasks while minimizing costs and safety risks.

Construction: Construction training in VR provides a virtual job site where learners can practice operating heavy machinery, erecting scaffolding, and following safety protocols. Simulations cover tasks like blueprint interpretation, equipment maintenance, and hazard identification, ensuring a comprehensive understanding of construction site dynamics. Trainees can experience the challenges of navigating complex worksites and making real-time decisions, all within a zero-risk environment that prioritizes safety and skill development.

HVAC: VR training for HVAC professionals offers realistic simulations of diagnosing, repairing, and installing heating, ventilation, and air conditioning systems. Trainees can practice troubleshooting issues like airflow problems, refrigerant leaks, or malfunctioning thermostats without handling live systems. Virtual environments replicate various building layouts and climate conditions, giving learners hands-on experience in a wide range of scenarios. This approach ensures trainees develop a deep understanding of system components and safety protocols, preparing them for the complexities of real-world HVAC tasks.

These applications demonstrate how VR is not just a theoretical concept but a practical tool reshaping the landscape of job training.

Benefits for employers and training centers

The impact of VR extends beyond trainees. Employers and training centers also stand to gain significant advantages:

Reduced Downtime: Training employees on-the-job often disrupts workflows. VR minimizes downtime by enabling employees to train off-site or during non-peak hours.

Scalability: With VR, training can be scaled to accommodate large numbers of learners simultaneously, making it ideal for companies looking to onboard multiple employees or upskill their workforce.

Improved Talent Pipeline: By incorporating VR into certification programs, training centers can better prepare candidates for the workforce. This ensures employers have access to highly skilled workers, reducing the time and resources spent on additional on-the-job training.

Virtual Reality is not just a technological innovation—it’s a paradigm shift in how we approach job training and certification. By creating immersive, safe, and cost-effective training environments like the ones offered by ImmerseLearn, VR addresses the limitations of traditional methods while preparing workers for the demands of the modern workforce.

As industries continue to embrace VR, its role in shaping skilled trade certification will only grow, solidifying its place as the future of job training. Whether you’re an employer, training center, or aspiring tradesperson, now is the time to explore how VR can transform your approach to skill development and certification.

Are you ready to experience the future of job training?